Baoji Titanium Industry Co., LTD .was established on July 21th 1999, founded by BAOTI Group on April 12 2002,Baoji Titanium Industry Co., LTD was listed on Shanghai Stock Exchange. As one of the world leading professional titanium alloy producer, it is the largest titanium alloy R&D base in China, it also isNational high-tech enterprises, its location is honoured as The Titanium City of China or China Titanium Valley.

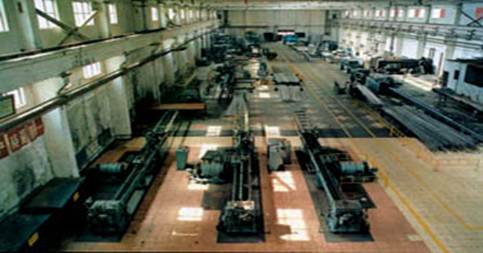

After 50 years of accumulation and development, the company established a "sponge, casting, forging, sheet, strip, seamless pipe, welded pipe, bar, wire, precision casting, raw material handling," ten major production systems, have production capacity such as 30,000 tons of titanium ingot and 20,000 tons of titanium processing materials.Company main equipment are introduced from the United States, Japan, Germany etc. 15 countries, such as 2400kw EB furnace, 15/10 tons consumable vacuum arc furnace,10,000 tons open-die forging press, 2,500 tons high-speed forging press, high speed wire rod production line, titanium strip coil production line (MB22-Tl type of 20-high cold rolling mill), 3.3 meters broad plate production line represents the international advanced level, which makes our country become the United States, Japan and Russia after the fourth country with a titanium complete industrial chain.

Companies increase scientific and technological innovation and new product development. The main products cover titanium and titanium alloy plate, strip, foil, tubes, rod, wire, forgings, castings, etc., and gradually extend to zirconium, nickel, steel and other materials. Products are widely used in aviation, aerospace, ships and other high-tech fields and alkali chemical industry, electric power, metallurgy, medicine and Marine engineering important areas of the national economy.

By implementing the growth strategy, we can achieve leapfrog development in capital market. The company actively expand the international market, products are exported to the United States, Japan, Germany, France, Britain, Italy, Norway, Sweden, Singapore, India, South Korea and other dozens of countries, with Airbus, Boeing and other international well-known aviation enterprise established long-term strategic cooperative relations, gradually become an important part of the world of titanium industry.

Titanium sponge

Since 2007, BAOTI Group invested 450 million yuan with cooperation with jinzhou huashen to found The Baoti Huashen Titanium Industry Co., Ltd, which set up including "chloride, refined, reduction distillation, electrolytic" whole process titanium sponge production system, the company holding 66.7%.The annul sponge production capacity has reached 10,000 tons, 500 tons of zirconium sponge. The company passed the attestation of system of weapons and equipment, military specifications and aerospace related, mastered the low oxygen nitrogen titanium sponge production technology. Product quality is stable, reliable. Titanium sponge first-grade product rate reaches 90% above that in the domestic leading position.

Melting

BAOTI Group has imported the world first class equipment such as 2400kw EB furnace, 10 tons consumable vacuum arc furnace, automatic raw material’s blending and distributing systems, 8000t 7000t 3000t oil press and vacuum plasma welding chamber etc. from Germany, building the international leading titanium ingot production system. The company is in the international leading position in the titanium alloy composition, metallurgical quality control and so on, started the first way to EB furnace industrialization production pure titanium, titanium alloy ingot in domestic.

China's first 10t titanium ingot, the first EB furnace 10t titanium flat ingot, was born in BAOTI.

We can produce standard production domestic and overseas a variety of grades, specifications Φ 1040 mm 15 tons ingot and the single largest 10 tons of flat ingot.TC4 alloy ingot won the national gold medal.

Forge

With the advanced 10,000 tons open-die forging press, 2,500 tons high speed forge machine ,domestic 3150 ton hydraulic press, CNC rolling machine. SXP-13 precision forging press imported from Austria, Among them, the latest investment of about 400 million is the largest 10,000 ton free forging machine introduced by the world titanium industry, which is the most advanced forging machine in the world with the fastest forging speed, the highest precision and the control system.

Relying on advanced equipment, the company successfully developed TC4DT, TB6, TC17, TC18 titanium alloy bars, TC21 and TA19 big specification, the quality has reached the international aerospace rotating parts, structure standard, which satisfy the needs in the field of aviation, aerospace, shipbuilding, etc.

It has won the national gold award and provincial excellent product award, and the large size forging bar is in the international leading level.

bars maximum diameter 600mm

disk largest diameter 2000mm

ring maximum diameter 3000mm

spherical part maximum diameter 2000mm

Sheets & Plates

With the 3.3 meters reversible hot rolling mill imported from Germany, 1.2 meters 4-high reversible hot rolling and cold rolling mills imported from Japan, and with the vacuum annealing furnaces, grinding machines, it consists of the first class production system for titanium plate and sheet.The annual output of plate can reach 5000 tons

Hot rolling thickness max 102mm

Width max 3200mm

Cold rolling thickness 0.3mm~4.75mm

Width max 1219mm

Thickness of 1.5 mm below the titanium alloy plate adopts the world advanced process that is explosion-rolling , the plate has good type, high dimensional accuracy and the outstanding performance. thickness of less than 0.8 mm of titanium alloy sheet is in the international advanced level. For China's deep-sea submersible project, the thickness of 90mm x 3200mm x 3200mm x 3200mm is a large size of TC 4 wide plate.

The company TC4 and other brand alloy sheet metal products with its excellent quality and performance, is favored by Boeing, Airbus, Goodrich and other international famous aerospace enterprises.

Strip

Company invested 733 million RMB to set up a strip production line,With the MB22-Tl type of 20-high cold rolling mill and special process system imported from Germany,with a capacity of 10,000 tons. The cold rolling strip thickness ranges from 0.3 to 4.75mm and width from 600~1,370mm.

A joint venture, invested by Baoji Titanium Industry and Shanxi Taigang Stainless Steel was set up to extend product category and increase market share.

Seamless Tubes

For tube production, we have equipment including 3,150t extrusion machine, 1,000t piercing machine, vacuum annealing furnaces and several tube rolling mills. Tube capacity is 2,500 tons per year and bar 1,000 tons.

Welding tube

It is a joint venture invested by baoti industry and Valtime S.A.S of France, changzhou farino Great Wall welded pipe co., LTD and Timet Asia of the United States. It was established in 2005.

The two production lines and main equipment and testing equipment are imported from the United States, Germany and France.

The automatic titanium welded pipe production line adopts the French non-melting tungsten electrode argon arc welding pipe technology, single-site welding speed can reach 8m/min, which is the world's leading level.

The outside diameter of the welded pipe is 10 ~ 40mm, and the wall thickness is 0.3 ~ 2.1mm.

Products have been widely used by domestic steam turbine industries such as Dong Qi, Harbin auto.

Bars & Wires

Baoji Titanium Industry invested 400 million RMB to set up the first hot continuous rolling line for titanium and titanium alloys in China. It has facilities of rolling line, S100 and S60 barkers, rolling mill, handstand type drawbench, multiroll straightener, vacuum induction furnace and anti-vacuum induction furnace. Titanium bars and wires capacity is 2,000 tons per year and steel bars and wires capacity 300,000 tons.

We can produce 0.8 ~ Φ 120 mm diameter bar wire, the precision of + / - 0.02 mm, surface roughness Ra 0.8 ~ 1.6 microns, the precision can reach grade h7 tolerance size and surface roughness Ra≤0.8μm.

It can also produce high value-added titanium and titanium alloy profiles, zirconium, nickel and stainless steel products such as hexagonal rod, splint plate and frame wire.

The titanium alloy bar such as TC4, TC6, TC11 and TA11 used in the air compressor blades meet the requirements of the national military standard. The bar wire product is also used in medical surgical implants, aviation fasteners and other fields.

Scrap Recycling

Baoji Titanium Industry invested 130 million RMB to set up its titanium and titanium alloy scrap recycling system with a disposal capacity of 5,000 tons per year.

With the crusher, block material cleaning machine, air separator, magnetic separator, X ray on-line inspection system and other advanced imported equipments,it formed a completely scrap process lines, and the capacity of processing scrap reached 5,000 tons per year.

It has become an important support for the company to develop circular economy, reduce production cost and improve competitivenes

Precision Casting

Baoji Titanium Industry set up a precision casting system with a capacity of 250 tons per year.It has 25Kg, 150Kg, 500Kg vacuum coagulation furnace, large graphite degassing furnace, CNC processing center, wax injection machine and other equipment.The company is constructing a production line for golf club head, whose capacity is expected to be 200,000 per year.